Our page uses cookies

We use cookies to personalize and enhance your browsing experience on our website. By clicking "Accept All", you agree to use cookies. You can read our Cookie Policy for more information.

Make Food Production Easier

Sign up

Your Position:Home>

Your Position:Home>Our latest biscuit production line is engineered to facilitate the production of both soft and hard biscuits on a single line. In fact, modern biscuit production lines are typically designed as versatile and multipurpose systems, capable of accommodating the production of various types and textures of biscuits.

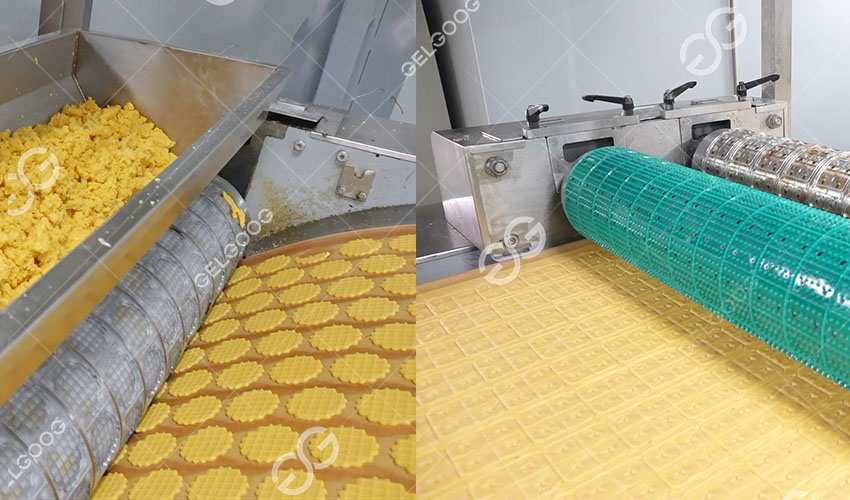

The operating principle of our latest biscuit production line is straightforward. The well-prepared dough is first poured into the hopper, and the forming machine automatically presses the dough into shape.

Principles of Hard Biscuit Production:

The process begins by placing a dough made from wheat flour, sugar, edible oil, spices, and water into the hopper of the forming machine. The dough is rolled out by cylinders, then conveyed through a canvas conveyor belt to the second and third forming machines, where it is pressed into the appropriate thickness. Subsequently, a biscuit dough cutting machine cuts the formed dough into biscuit shapes. The formed biscuit dough is separated from excess dough by a conveyor belt, with the formed dough being transported to a tunnel oven conveyor belt and the excess dough recycled into the hopper for re-pressing into new dough. After baking, oil spraying, and cooling, the biscuits are ready for consumption.

Principles of Soft Biscuit Production:

Before producing crispy biscuits, the cutting molds for producing firm biscuits are removed, and printing molds, feeding rollers, engraving knife shafts, engraving knives, and printing material hoppers are installed. The adjustment axis of the canvas conveyor belt between the third route and the mold is pulled out, and a canvas belt is adjusted to separate the cutting part of the skin roller from the power supply. Mixed dough is then placed in the printing material hopper, and through the mutual squeezing between the feeding roller, printing roller mold, and splitting knife, it is shaped into the appropriate dough. Afterward, the biscuits go through baking, oil spraying, and cooling, resulting in crispy biscuits.

Our latest biscuit production line simplifies the entire biscuit-making process, offering ease of operation and stable equipment performance. The production of biscuits with varying textures, whether resilient or crispy, is achieved through straightforward steps, including the simple interchange of molds. If you are interested in our equipment, please feel free to contact us.

Link: https://www.gelgoogsolution.com/solution/biscuit-cookies-line.html Contact Email: isle@gelgoog.com WhatsApp/Wechat: +8618538123076

E-Mail

isle@gelgoog.com

E-Mail

isle@gelgoog.com

Contact

0086-18538123076

Contact

0086-18538123076

Whatsapp

0086-18538123076

Whatsapp

0086-18538123076

TOP

TOP

We use cookies to personalize and enhance your browsing experience on our website. By clicking "Accept All", you agree to use cookies. You can read our Cookie Policy for more information.